Motors and More Sparks

This got me thinking about motors - I need to understand the motor wiring a little. A quick review of the two motors showed that, as supected, LittleJohn lathe no2 has a newer Crompton-Parkinson motor fitted, now Brook-Crompton, type number VSA534HH3A, 0.33BHP@ 1425rpm. The motor mount looks to have been redrilled for this motor, and I am guessing that is replaced the original motor, but as Crompton-Parkinson has now changed names, this must be some time ago.

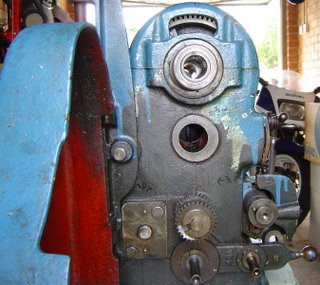

LittleJohn lathe no1 has a Metropolitan-Vickers BS2418 motor, 1/2 hp @ 1425rpm. It says Quote D165710S for spares. Since Metropiltan Vickers has not existed as a name since 1960, I assume it is the original motor. It also has a nice cast iron bracket bolted to the top of the motor, and a forward/reverse roller switch that looks original. The switch is nicely positioned just above the top cover.

This places me in a slight quandry, as I would have liked to keep the original motor, especially since it is higher power, but am concerned that a 40 year old motor may need replacing sooner rather than later.

Back to the Brook Crompton motor website, there are four terminals (plus earth) - Z1, Z2 and U1,U2. Z1 and Z2 are the start winding, U1 and U2 are the run winding. I guess that the the motor is reversed by swapping over either U1, U2 or Z1, Z2.

I havent had a look under the MetVick cover yet to see what the wiring is about. Since there are four wires, I guess it must be the same as the Brook-Crompton.

More details top follow...