Review of LittleJohn Mk1 Number 2

Had a chance to review machine number two today. This was the machine that was bought from Manchester, and known to have damage. It is serial number 0640, for those interested.

First Glance

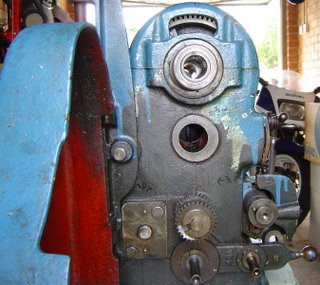

At first glance, everything looks OK. There is a neat 4 post tool holder, a chuck (not shown) and tailstock. When I collected, the guy explained there was some damage to the gears, caused by him trying to remove the chuck the wrong way, but it powered up OK and the variator worked and sounded OK. He had been using it as a plane lathe since, but now wanted rid. It looked very similar to a picture of a lathe on the Yahoo Groups forum from Ebay. A look under the cover showed something not quite right. The backgear and power feed drive gubbins were absent.

A look under the cover showed something not quite right. The backgear and power feed drive gubbins were absent.

The good bits were that the motor was a replacement, so relatively new.

The Details

According to Tony's page on the LittleJohn, the lathe came with 2 x 30t, 32t, 36t, 42t, 44t, 45t, 48t, 52t, 60t changewheels as standard, plus the 52t and 44t metric conversion wheels and a pair of 48th wheels for imperial.

The bag of bits contained: 30t free, 30t bushed, 44t, 3 x 48t and a 60t changewheel. Compare the picture with Tonys Raglan page below.

Plus, a chipped backgear assembly, chipped 38t main power drive, chipped 76t with good 30t, and good small reversing gears, including the fragile brass one. Looking under the top bearing cover (where the LittleJohn name is) showed further damage to the backgear with the engagement pin.

Plus, a chipped backgear assembly, chipped 38t main power drive, chipped 76t with good 30t, and good small reversing gears, including the fragile brass one. Looking under the top bearing cover (where the LittleJohn name is) showed further damage to the backgear with the engagement pin. Speaking practically, if I only want to cut metric threads in the common sizes of 0.75, 1, and 1.5mm pitch, then I only need (apart from the 44 and 52t gears) 2 x 30t, 32t, 36t, 2 x 45t and 48t, as read from the plate on the lathe. Note that 0.8mm was missing, but I will worry about that later.

Speaking practically, if I only want to cut metric threads in the common sizes of 0.75, 1, and 1.5mm pitch, then I only need (apart from the 44 and 52t gears) 2 x 30t, 32t, 36t, 2 x 45t and 48t, as read from the plate on the lathe. Note that 0.8mm was missing, but I will worry about that later.

The previous owner had removed all the backgearing and cam operated lever, so it would operate ungeared at 1750-270rpm for using the variator for spindle speeds. Also included was a roughed out blank for the 38t main power feed from the spindle, but I doubt I will use it. The last picture shows the gear cover was cracked and repaired, possibly before I was even born!

0 Comments:

Post a Comment

<< Home